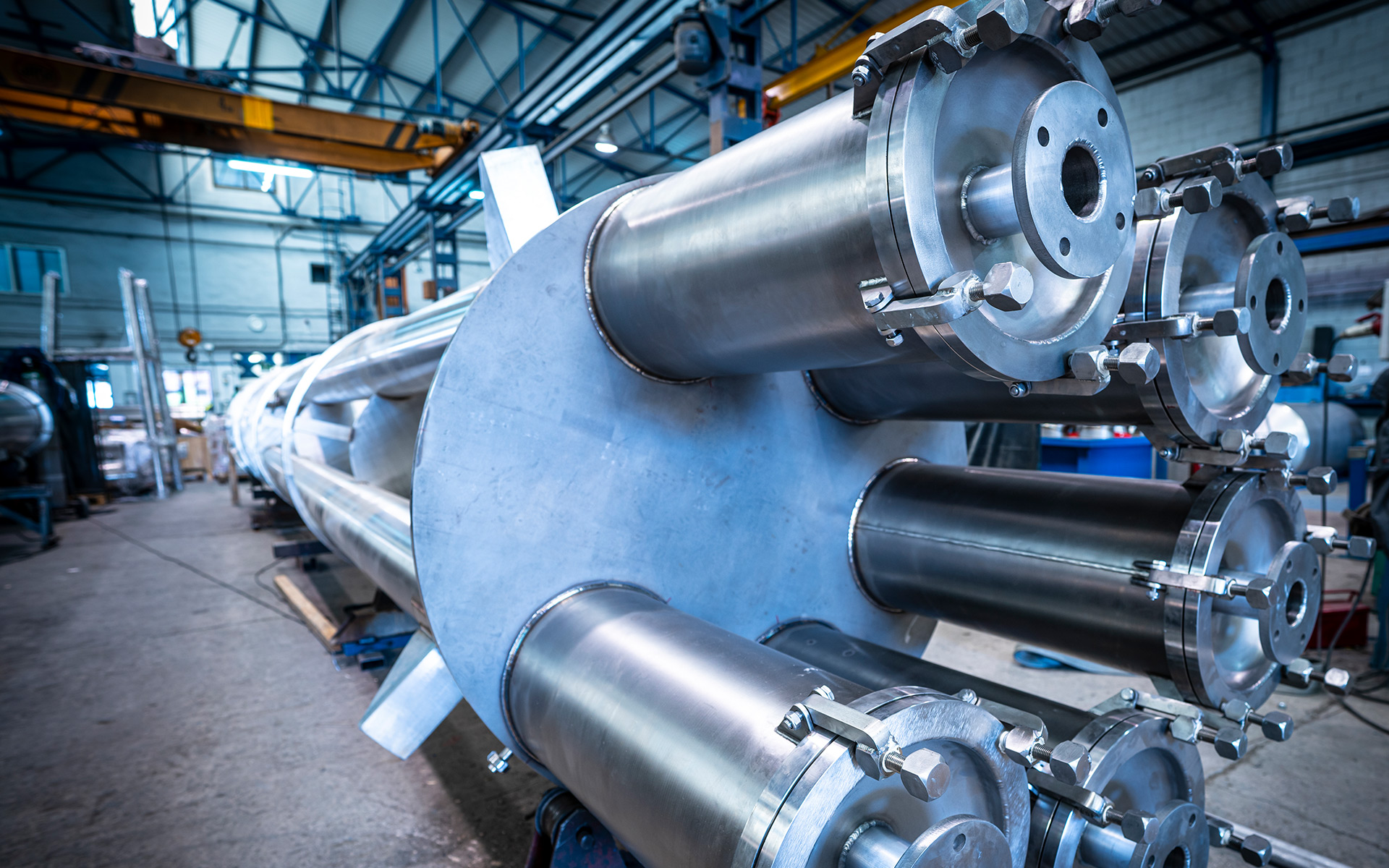

Welcome to TT Craft – your welding expert for valves, pressure vessels and sampling systems. We take on your welding work when you need a reliable supplier. Applying the Pressure Equipment Directive, we manufacture pressure vessels, non-pressure vessels, product tanks, storage tanks, tubs or open containers, mixing tanks, mobile containers, or custom solutions for you. We can also manufacture cooled or heated containers with or without media connections.

As a manufacturer of valves and sampling systems, we are designed to provide you with optimal performance and reliability. We understand the importance of precise sampling and ensure that your systems meet the highest quality standards. We are happy to take on pressure tests up to 1000 bar, dye penetrant testing according to ISO 9712 PT2, or coordinate X-rays with our partner TÜV NORD EnSys GmbH & Co.

Give us a call or send us an email. If you need support for your project, we will surely find a way.

Overview of our services in apparatus and container construction:

-Stahlprobenbehälter - Entwickelt und gefertigt durch Firma Kark GmbH, geschweißt durch TT Craft UG

Manufacture of reservoirs, tanks and containers

Industrial vessels are typically designed for the specific needs at hand. Depending on the volume, desired material properties or function, fundamentally different containers can result. From robust and durable steel tanks, universal stainless steel pressure vessels to special chemical containers made of special metals such as Duplex, CuNiFe or titanium. These metals offer outstanding properties such as high resistance to aggressive chemicals, extreme temperatures, or pressures. Our chemical containers made of special metals are precisely manufactured and meet the highest standards in terms of quality, safety, and performance.

Edelstahl Behälter WIG Schweißen

Edelstahl Behälter Montage

Manufacture or apparatus

When it comes to the production of sophisticated apparatuses and assemblies, we are your reliable partner in and around Hamburg. On your behalf, we carry out complex welding jobs, whether as a large or small order, you are in the best hands with us. With our hole pattern tables, we ensure a perfect alignment of the parts with each other. With a pattern of holes that are strategically placed for various purposes, such as aligning and securing parts during assembly or welding processes. The holes in the table allow for flexibility in positioning and clamping components, providing a stable and precise work surface. Our modern and clean working environment allows us to work with precision and efficiency.

Our goal is to deliver products that meet your expectations in every aspect.

Edelstahl Sonderapparatebau

Edelstahl Sonderapparatebau

Inspections and Product Approvals

Irrespective of the origin of the request for a product acceptance, whether from your customers, regulatory guidelines, or for your own purposes, we assist you with the required inspections:

- Endoscopy and visual inspection according to ISO 9712 VT2

- Dye penetrant testing according to ISO 9712 PT2

- Magnetic particle testing according to ISO 9712 MT2

- Radiographic testing according to ISO 9712 RT2

- Ultrasonic testing according to ISO 9712 UT2

- Leak tests (internal pressure tests) up to 1,000 bar

- External pressure tests up to 800 bar

- Work samples for laboratories

Our expertise includes, among others, endoscopy and visual inspection according to ISO 9712 VT2, dye penetrant testing according to ISO 9712 PT2, magnetic particle testing according to ISO 9712 MT2, radiographic testing according to ISO 9712 RT2, and ultrasonic testing according to ISO 9712 UT2.

With endoscopy and visual inspection, we can identify hidden defects and irregularities, conducting a thorough examination. Dye penetrant testing employs state-of-the-art techniques to detect surface defects and ensure your components meet the highest quality standards.

Magnetic particle testing allows us to detect cracks and defects in magnetizable materials. Radiographic testing provides detailed insights into the structure and quality of your components, while ultrasonic testing enables us to identify surface and volumetric flaws precisely.

Our range of services also includes internal pressure tests up to an impressive 1.000 bar and external pressure tests up to 800 bar. These tests are crucial to ensuring the integrity and reliability of your components under extreme operating conditions.

Regulations – The Pressure Equipment Directive

In virtually all developed countries, numerous regulations govern the manufacturing of safety-critical products. In Europe, the Pressure Equipment Directive (PED) applies to pressure equipment placed on the market in the European Economic Area (EEA). In the United States, the ASME Code is applicable, and in China, it is the SELO license. To offer products and services in these regions, businesses must be certified according to the respective national regulations. This certification requirement applies across the entire manufacturing chain, especially for suppliers to machinery manufacturers.

We are certified by TÜV Nord according to AD 2000 HP0 and EN 13445, which authorizes us to manufacture vessels under the European Pressure Equipment Directive. Additionally, we hold a limited special approval for ASME. Further certifications for other industry sectors can be found in the “Approvals” section.

![Zertifizierung nach AD 2000 HP0, HP 100R, DIN 13445-4 / 13480-4 Logo vom TÜV Nord für eine erfolgreiche Zertifizierung nach AD 2000 HP0, HP 100R bzw. DIN 13445-4 / 13480-4 [Druckgeräterichtlinie]](https://www.tt-craft.de/wp-content/uploads/2023/07/DGRL.png)

Pressure Equipments

AD 2000 HP0, HP 100R

DIN 13445-4 / 13480-4

Metal Workshop

ISO 3834-2

Restamping

EN 10204

Sustainability

Guideline within

the company

[ISO 14001 planned 2024]

Defence Technology

DIN 2303 Q2 BK1

Apprenticeship employer

Chamber of Crafts

Six Reasons to choose TT Craft

- With up to 1.200 work-hours per month, we have sufficient capacity for your projects.

- We are flexible and can usually provide support on short notice.

- We have extensive knowledge of applicable regulations and can advise you accordingly.

- You’ll get quality with us: X-ray-proof welds, level flanges and connections, and clean work.

- Documentation and evidence reports that are complete and accurate.

- Environmental protection and occupational safety at a high level, giving you peace of mind.