We collaborate successfully with numerous small and medium-sized machining companies for whom establishing their own small welding shop is simply uneconomical due to the high requirements.

Overview:

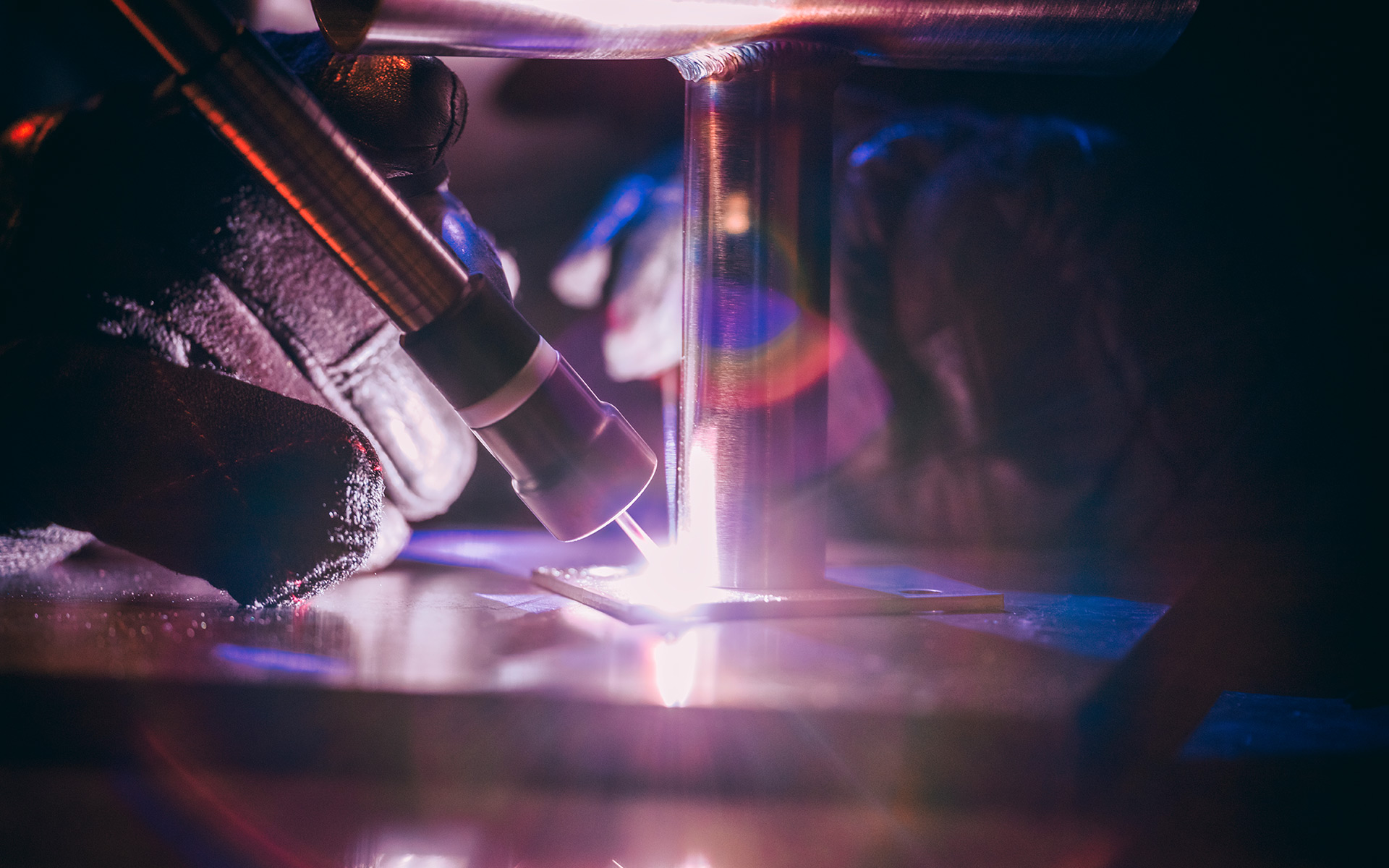

TIG and MSG Welding by Hand

The two most widely used welding processes form the backbone of welding technology. Especially in the case of low quantities, intricate component geometries, or prefabrications with undefined geometry, welding by hand remains the prevalent method. These two welding processes are highly versatile and have been economically employed for decades. They are well-suited for repairs or modifications as well. Typically, the products fall within the scope of the Machinery Directive 2006/42/EC or the new EU Machinery Regulation (EU) No. 2023/1230 as of June 29, 2023. We are well-equipped to handle any products with our certification according to ISO 3834-2.

WIG Schweißen von Sonderkonstruktionen

MAG Schweißen von einfachen Stahlteilen

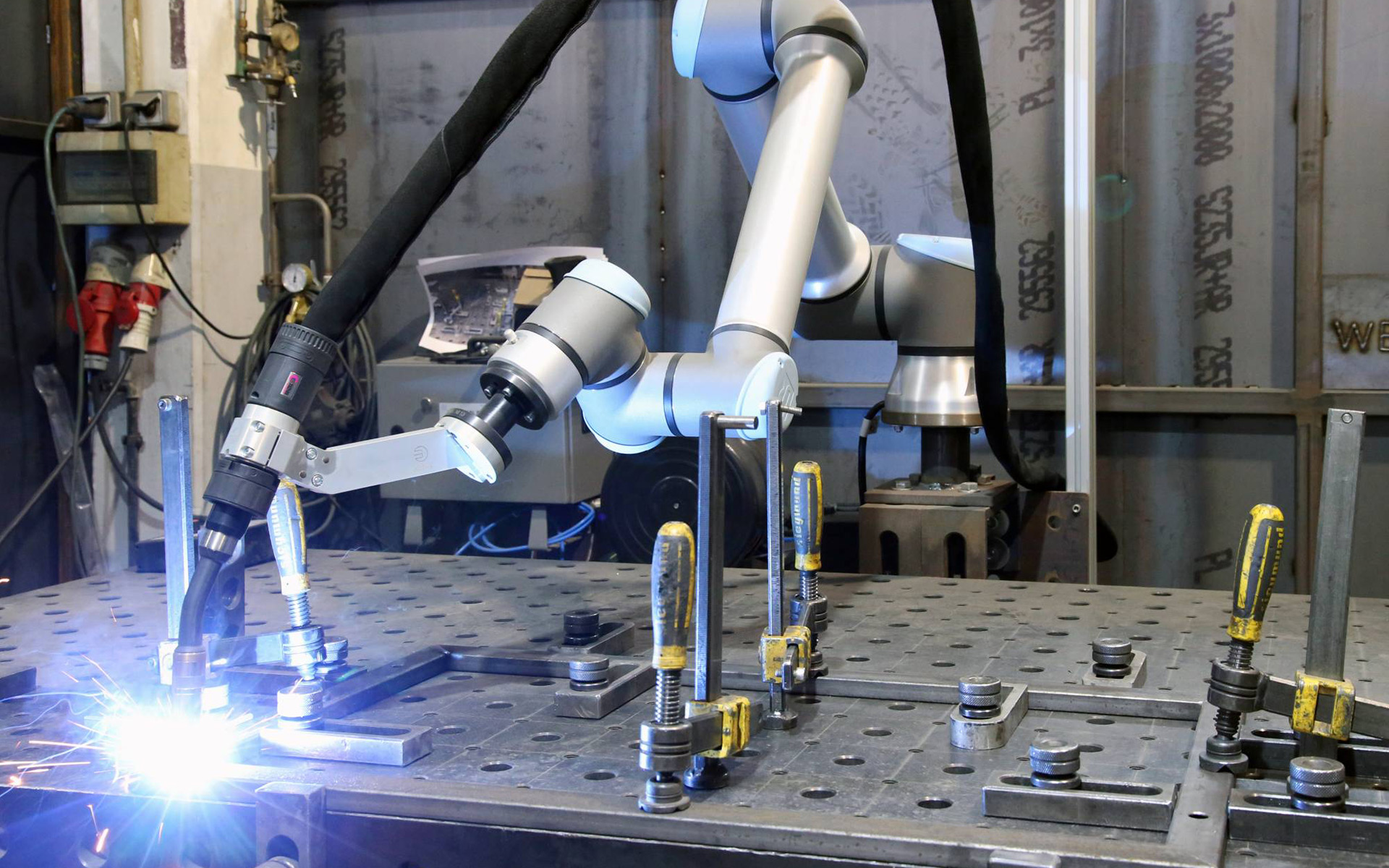

MSG Welding in Series with State-of-the-Art Robotic Technology

Do you have a small series of around fifty to several hundred components? The individual parts of the subsequent welding assembly can be well-produced mechanically and are therefore largely identical? In that case, a MSG welding robot can be effectively utilized. Ideally, an operator certified according to DIN EN ISO 14732 works in harmony with the robot at adjacent workstations. While the welding robot tacks and welds an assembly, the operator beside it removes a finished assembly from a fixture and reloads it with individual parts. This ensures a consistently high quality, and the products remain cost-effective.

MAG-Schweißen Robotertechnik

Various metals

At TT Craft, we take pride in welding a broad range of metals, from conventional steel to advanced materials such as stainless steel, aluminum, copper-nickel and even titanium. We strive to master the unique properties and challenges of each metal, adapting our welding techniques accordingly to achieve optimal results. Precision and the quality of our work are always paramount.

With our extensive experience, we can effortlessly handle unusual alloy combinations. Whether you require X-ray-proof weld seams or other specifications, we rely on our deep expertise and state-of-the-art equipment to exceed your expectations.

Read on to learn more about our welding services for individual metals:

Welding Steel and steinless steel

Steel is a versatile material widely used in industrial plant and pipeline construction. Our experienced team has no problems with welding steel in various forms and sizes.

Stainless steel is known for its corrosion resistance and hygienic properties. We provide customized stainless steel welding solutions for various applications, whether in the food, chemical, or pharmaceutical industries. Count on us to deliver high-quality welds that adhere to the strictest quality standards.

Furthermore, we offer a variety of other welding techniques, such as black-white mixed compounds, pipe-in-pipe welding, and TIG mirror welding.

Edelstahl schweißen

Stahl schweißen

Stahl-Edelstahl Mischverbindung schweißen

Rohr-in-Rohr schweißen

Duplex and high alloyed Austenitic Steels

In addition to common stainless steels such as 1.4301, 1.4305, and 1.4571, we also process duplex steels like 1.4462 and highly alloyed austenitic steels such as 1.3954, 1.3964, and 1.4539. These special metals are known for their extreme corrosion resistance and mechanical strength. They offer excellent resistance to corrosion, erosion, stress corrosion cracking, and many chemical substances. These materials are ideal for applications where high reliability and durability are required.

Welding Aluminum

Aluminum is a relatively lightweight material commonly used in lightweight constructions, particularly in aircraft manufacturing. Aluminum pipelines are also not uncommon, known for being lightweight yet robust, chemically resistant, providing good thermal and sound insulation, and serving as excellent conductors of electricity. Welding aluminum requires specific expertise and techniques.

Rohrleitung aus Aluminium schweißen

Aluminium WIG Schweißen

Welding Copper-Nickel

Copper-nickel alloys (CuNi) are often used in maritime applications due to their high resistance to corrosion and wear. At TT Craft, we have the expertise and necessary equipment to ensure precise welding connections for copper-nickel components. Naturally, we can also provide you with the two mixed compounds CuNiFe-stainless steel and CuNiFe-steel.

TIG welded groove weld of a mixed joint made of CuNiFe and Stainless Steel

CuNiFe schweißen

CuNiFe-Edelstahl Mischverbindung schweißen

Welding Titanium Alloys

Titanium is an extremely robust and lightweight metal used in demanding high-tech fields such as aerospace, medical technology, and notably in the maritime sector. Due to its excellent corrosion resistance, titanium is unaffected by saltwater or moisture and maintains its integrity and performance even under extreme conditions. It is also resistant to fatigue and stress corrosion cracking, crucial for underwater components subjected to high loads. Additionally, titanium is biocompatible and compatible with marine life, making it a preferred material for the maritime sector, offshore structures, underwater exploration, and shipbuilding.

Titan schweißen